Agriculture

November 9, 2023

VF 100 Village Bucket Filter

Read SolutionImplemented by

Village Water Filters, Inc.

Updated on November 9, 2023

·Created on September 28, 2018

NVTerra produces and sells the NVAqua UF-100 water treatment, an automatic system capable of purifying 100 m3/day of raw surface water.

The NVAqua UF-100 plant is designed to ship ready-to-use in a container and run automatically, adjusting dosages of chemicals based on water quality monitoring. The system requires addition of salt, iron, and energy to run, producing all other treatment chemicals in-situ. The treatment steps are: Coagulation with Ferilec produced in situ, Biofiltration, Disinfection with hypochlorite produced in-situ, Reducelf, Sand filtration, Activated carbon filtration, Microfiltration, Ultrafiltration.

Target SDGs

SDG 6: Clean Water and Sanitation

Market Suggested Retail Price

$465,000.00

Target Users (Target Impact Group)

Distributors / Implementing Organizations

NVTerra, a Swiss water engineering company, manufactures, sells, and provides support for all NVAqua® treatment plants.

Manufacturing/Building Method

The NVAqua UF-100 is manufactured in Switzerland and comes in a shipping container assembled and ready to use.

Intellectural Property Type

Patent Protected

User Provision Model

Users can obtain the product through direct sales from the manufacturer.

Distributions to Date Status

Three sales and installations of the treatment plant in the Ivory Coast in 2016

Design Specifications

The UF-100 can treat turbid waters up to 1,500 NTU and removes all heavy metals, nutrients, pesticides, herbicides, hydrocarbons, and coliforms with a water recovery rate of 90%. In one hour, it produces 4.167 cubic meters (100 m3/day) of treated water and requires 4.8 kWh of electricity, 144 grams of salt, and 12 grams of iron. The electrical needs can be met by solar panels in off-grid scenarios. The treatment steps are coagulation, sedimentation, biological treatment, disinfection, oxydoreduction, sand filtration, activated carbon filtration, microfiltration and in some cases, depending on the composition of the water, ultrafiltration or nanofiltration or reverse osmosis.

Technical Support

There is no complex pre-installation; it is possible to operate the NVAqua® unit directly into the container, converted and equipped with solar panels where appropriate. In this case, only concrete flooring, a delivery pipe for the unsafe water and an outgoing pipe for the drinking water are needed. The manufacturer, NVTerra, can train local technicians to use the computer program that displays operational data and assist them via the remote control system.

Replacement Components

The plant requires 32 grams of salt, 3 grams of iron and 1.1 kWh energy per cubic meter of treated water produced. The filter media needs replacement every 3 years and costs $600 - $1,750 (500 ~ 1500 €) The pumps and electrodes need maintenance every 5 years and cost $1,200 - $2,300 (1000 ~ 2000 €) Replacement components can be ordered from the manufacturer.

Lifecycle

With proper maintenance and replacement of components, the NVAqua® UF-100 can last 20 years or longer.

Manufacturer Specified Performance Parameters

Meet WHO standards for Drinking water treatment from turbid up to 1,500 NTU river water with 90% recovery. The treatment process also produces excess sodium hypochlorite, or household bleach, which can be collected and used to clean the facility or sold for profit.

Vetted Performance Status

Two Swiss laboratories conducted analyses in 2009 for treatment performance of the unit using muddy canal water spiked with toxic contaminants. The test results on samples taken only after the first two stages of treatment showed that the units were effective in reducing concentrations of nitrates, phosphates, arsenic, lead, and cadmium. The flow of raw water input was 4.550 liters per hour and its turbidity was 65 UT/F90.

Safety

There are no hazardous chemicals needed, only salt and iron which can be safely stockpiled without extra precautions. Handling of sodium hypochlorite (bleach), a byproduct of the treatment process, requires the use of gloves and face masks in an enclosed area to prevent exposure to skin or inhalation of fumes.

Complementary Technical Systems

Safe water storage tank or tower for distribution.

Academic Research and References

None.

Compliance with regulations

Meets WHO standards for drinking water treatment

Other Information

Winner of the 2009 EBN AWARD for Innovations

Agriculture

November 9, 2023

Implemented by

Village Water Filters, Inc.

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Implemented by

Aqua-cura

Agriculture

November 9, 2023

Implemented by

Aquagenx

Agriculture

November 9, 2023

Implemented by

Jung Uk Park, Myeong Hoon Lee, and Dae Youl Lee

Agriculture

November 9, 2023

Implemented by

Folia Water

Agriculture

November 10, 2023

Implemented by

3M

Agriculture

November 9, 2023

Implemented by

Tapp Global Design Inc

Agriculture

November 9, 2023

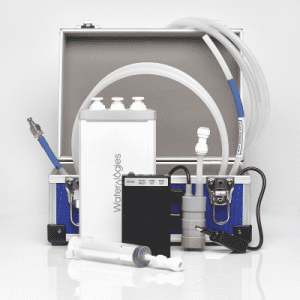

Implemented by

Waterologies

Have thoughts on how we can improve?

Give Us Feedback