Agriculture

November 9, 2023

Odon Device

Read SolutionImplemented by

Jorge Od├│n

Updated on November 9, 2023

·Created on September 1, 2021

Biobo is a composite wall panel that is made from recycled mycelia mushroom bio-waste, or mycelium.

Biobo (Binderless Bio-Board) is a 30×30 cm mycelium wall panel that is recycled from Mycotech Lab’s production waste and local agricultural waste, and is glued together without any chemical adhesives.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Mycotech Lab leather products can be ordered from their online store but there is no listing for Biobo

Manufacturing/Building Method

Mycotech Lab adopts what they call a “Circular Economy Practice” that incorporates their Mylea Leather production and waste into the life cycle of the Biobo Panel. The Biobo Panel is a composite board that uses recycled cutting waste from their mushroom products and bound together with mushroom mycelium as an adhesive. Unused mushroom waste from both these processes are composted as fertilizer that feeds back into the local agroforestry industry in West Java, Indonesia. The manufacturing cycle for Mycotech products (Mylea Leather and Biobo Panel) involves the same steps: Sieving, Sterilization, Incubation, Separation, Boiling, Dyeing and Drying, Tenacity testing, Pressing, and Cutting. Collaborating with local farmers, agricultural waste (cassava, corn, sugarcane, and sawdust) is collected, sieved, and packed into bags. The waste-filled bags are then sterilized in an autoclave. Once sterilized, spores are added to the bags and stored in an incubation room. Depending on the thickness and dimension of the product, local weather, and humidity, the bags are left in incubation for 14-30 days. After incubation, the mushroom material is separated for Mylea or Biobo use, the former has to be boiled in order to prevent fungal growth. After Mylea is dyed, both Mylea and Biobo are dried and made more durable. While the Mylea Leather is tested for tensile strength, the Biobo materials are pressed into a composite board that utilizes mycelium as a glue. Then, the board is cut into tiles of various sizes, the excess materials can be recycled to make a mosaic pattern in the creation of future Biobo panels. Currently, Biobo Panels are past the prototyping phase and are in mass production.

Intellectural Property Type

Patent Protected

User Provision Model

Those interested in Mycotech Lab products are invited to contact them through their website;

Distributions to Date Status

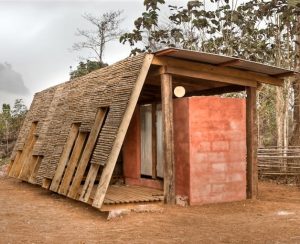

Number of units unknown. However, Biobo Panels have been used in collaboration with Urban-Rural Systems for the Batam Housing Project, a government-supported initiative to address growing housing demands in Batam, Indonesia while simultaneously implementing sustainable solutions. The Tropical Town project includes a series of houses (see two prototypes: Expandable House Part 02 and Rubah) designed by Urban-Rural Systems for this initiative.

Design Specifications

30 x 30 cm composite wall panels that can be cut to different sizes. While the primary use is to be a ‘living block’ that is more labor-efficient than brick, Biobo can also be used in furniture.

Technical Support

Provided by manufacturer.

Replacement Components

Unknown.

Lifecycle

Unknown.

Manufacturer Specified Performance Parameters

According to the manufacturer, BIOBO Panels are easier to install and have less carbon emissions than traditional building materials. The panels are also fire resistant and completely biodegradable. Designer specified performance targets include for company products (general): 100% nature-based polymers, animal-free production, low-carbon footprint, and 0% chromium in post production wastewater.

Vetted Performance Status

Compressive testing on mycelium-bound substrates were performed at the Karlsruhe Institute of Technology and Future Cities Laboratory (Singapore) in accordance with ASTM D3574 and in collaboration with Mycotech Labs;

Safety

There are no known safety hazards related to Biobo Panels.

Complementary Technical Systems

None

Academic Research and References

This paper presents information on Mycotech Lab’s mycelium technology and its application in a published structural project:

Heisel, FEliz et al. 2017, “Design of a load-bearing mycelium structure through informed structural engineering: The MycoTree at the 2017 Seoul Biennale of Architecture and Urbanism.” Paper presented at World Congress on Sustainable Technologies, Cambridge, 2017.

Compliance with regulations

The mycelium-bound substrate technology manufactured by Mycotech Lab complies with ASTM D3574;

Other Information

In 2019, Mycotech Lab received a B Company Certification within the Manufacturing Sector. Mycotech Lab also produced a Greenhouse Gases (GHG) measurement report as part of their waste production management goals.

Agriculture

November 9, 2023

Implemented by

Jorge Od├│n

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Implemented by

Ceramica Stefani Flex

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

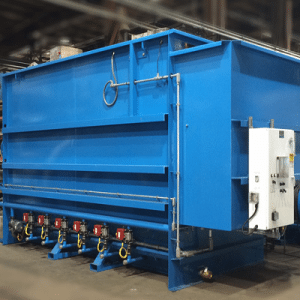

Implemented by

Safi Water Treatment Solutions

Agriculture

November 9, 2023

Implemented by

Aqus

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Have thoughts on how we can improve?

Give Us Feedback