Agriculture

November 9, 2023

Updated on November 9, 2023

·Created on September 1, 2021

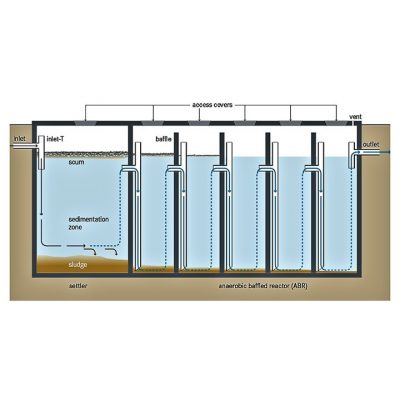

An Anaerobic Baffled Reactor (ABR) is an upgraded version of a septic tank and consists of a series of baffles designed to treat wastewater.

Anaerobic baffled reactors (ABR) are a sanitation technology designed to treat wastewater and fecal sludge through both physical and biological treatments. ABRs are improved versions of septic tanks where the addition of baffles in series increases contact time of wastewater and active biomass (sludge), which results in improved treatment.

The physical process includes settling. Prior to entering the ABR, the wastewater travels through a settling tank (sedimentation chamber), which removes the bulk of settleable solids. The biological treatment incorporates anaerobic digestion. As the wastewater travels through the baffles, the alternating upward and downward flows increases contact time between the wastewater and the residual sludge, which contains the microorganisms that anaerobically digest organic pollutants.

ABRs are relatively simple to operate and are resistant to hydraulic and organic shock loads, require no energy, have low operating costs, result in high reduction of BOD, and produce low amounts of sludge. The wastewater effluent and sludge from the ABR still require additional treatment. Therefore, ABRs are best used in combination with other treatment technologies and can be incorporated into decentralized wastewater treatment systems (DEWATS).

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

This product is manufactured globally, typically using locally available resources and labor.

Intellectural Property Type

Open Source

User Provision Model

Requires expertise in design and construction, but local technicians, NGOs, and governments have assisted in implementing ABRs.

Distributions to Date Status

Unknown

Design Specifications

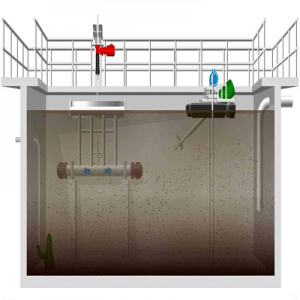

Possible influents: blackwater, greywater, brownwater, and fecal sludge Byproducts: biogas in addition to biosolids and effluent which require additional treatment for pathogen removal. Typical inflows: 2 - 200 m3/day. Hydraulic retention time (HRT): 48 - 72 hours Upflow velocity: less than 0.6 m/hr (not to exceed 2 m/hr) Organic load should be below 3 kg COD/m3/day Number of chambers: at least 1 sedimentation chamber & between 2 to 5 upflow chambers. Chamber sizes: less than 75 cm in length and less than 60% of the total height. In order to keep upflow velocities slower, the tanks should be kept shallow but can be made wider to adapt for larger loads. Vertical pipes or baffles can be used to connect chambers. Access ports are located on top of each chamber for maintenance. Venting is required to release the buildup of gases formed as a byproduct of anaerobic digestion. Although not typically collected, biogas can be collected and used to power certain power needs like operating pumps or cooking. No electricity required. Treatment process: The process should start with a settling chamber for removal of larger solids. Wastewater flows upward through the tanks, starting at the bottom where the wastewater is forced to pass through the sludge and interact with the activated biomass. As the wastewater travels through the baffles, the alternating upward and downward flows increases contact time between the wastewater and the residual sludge, which contains the microorganisms that anaerobically digest organic pollutants. The separate compartments allow for the HRT and SRT to be decoupled, enabling the wastewater to be treated on shorter time scales (hours). Start-up period for the ABR can be long due to slow growth of the anaerobic biomass. This start-up period can be shortened by inoculating the ABR with anaerobic bacteria from fresh animal dung. Use of the ABR should be incrementally increased over months to allow for new growth of anaerobic biomass.

Technical Support

Support provided by implementer or user.

Replacement Components

Unknown

Lifecycle

Generally long lasting, but depends on ABR size, number of chambers, and frequency of sludge removal.

Manufacturer Specified Performance Parameters

ABRs are designed to treat wastewaters, achieving up to 90% removal of BOD and TSS, and sludge, producing low amounts that are stabilized. ABRs have low operating costs, require no energy inputs, and are simple to operate.

Vetted Performance Status

Applicability of ABRs as solutions for handling blackwater treatment system with infiltration or effluent transport was discussed in Eawag’s Compendium of Sanitation Systems and Technologies (2nd Revised Edition). The appropriateness of anaerobic baffled reactors (ABRs) for on-site primary sanitation in low-income communities was evaluated using a pilot project testing COD removal in domestic wastewater. Results indicate that COD removal was sufficient for agricultural reuse but insufficient for discharging into surface or groundwater. The following study reports on the effectiveness of ABRs in removing organic pollutants.

Safety

Effluent and sludge must be handled with care since pathogens and nutrients are not removed. Effluent and sludge requires additional treatment.

Complementary Technical Systems

Requires water for flushing. Sludge and scum require regular removal (every 1 to 3 years). Sludge and scum removal strategy and technology including: road access for vacuum trucks (e.g. a Motorized Emptying and Transport technology) or a Human-powered Emptying and Transport Technology.

Academic Research and References

Tilley, E., Ulrich, L., Lüthi, C., Reymond, P., & Zurbrügg, C., 2014, Compendium of Sanitation Systems and Technologies (2nd Revised Edition), Swiss Federal Institute of Aquatic Science and Technology (Eawag), Duebendorf, Switzerland.

Foxon, K. M., Pillay, S., Lalbahadur, T., Rodda, N., Holder, F., & Buckley, C. A., 2004, The anaerobic baffled reactor (ABR): An appropriate technology for on-site sanitation, Water SA, 30(5), 44–50.

Sasse, L., 1998, DEWATS: Decentralised Wastewater Treatment in Developing Countries, Bremen Overseas Research and Development Association (BORDA), Germany.

Morel, A. and Diener, S., 2006, Greywater Management in Low and Middle-Income Countries: Review of different treatment systems for households or neighbourhoods, Sandec (Water and Sanitation in Developing Countries) at Eawag (Swiss Federal Institute of Aquatic Science and Technology), Dübendorf, Switzerland.

Singh, S., Haberl, R., Moog, O., Shrestha, R. R., Shrestha, P., & Shrestha, R, 2009, Performance of an anaerobic baffled reactor and hybrid constructed wetland treating high-strength wastewater in Nepal—A model for DEWATS, Ecological Engineering, 35(5), 654–660.

Bachmann, A. ; Beard, V. L. ; McCarty, P. L., 1985, Performance Characteristics of the Anaerobic Baffled Reactor, Water Research, 19(1), 99-106.

Barber, W.P. ; Stuckey D.C., 1999, The use of the anaerobic baffled reactor (ABR) for wastewater treatment: A review, Water Research, 33(7), 1559-1578.

BORDA, 2009, EmSan—Emergency Sanitation—An innovative & rapidly applicable solution to safeguard hygiene and health in emergency situations, Bremen Overseas Research and Development Association (BORDA) & BORDA BNS Network.

Stuckey, D. C., 2010, Anaerobic Baffled Reactor (ABR) for Wastewater Treatment, Environmental Anaerobic Technology, 163-184.

Compliance with regulations

Depends on national regulations. Can sometimes meet standards for agricultural application, but not surface water or groundwater discharge.

Other Information

None

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Have thoughts on how we can improve?

Give Us Feedback