Agriculture

November 9, 2023

Updated on November 9, 2023

·Created on September 27, 2018

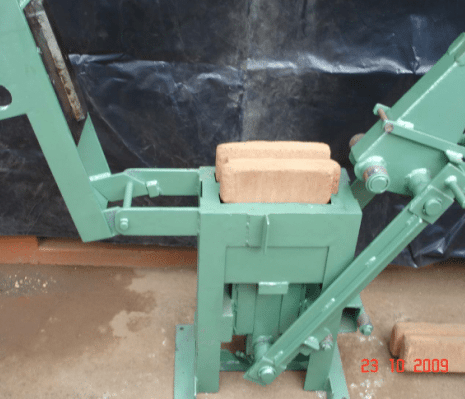

The Stabilized Soil Block Press by Makiga is a manual machine that can be used to press 500 bricks in a day. There are four different machines for various block shapes: straight interlocking blocks, wide straight interlocking blocks, curved interlocking b

The Stabilized Soil Block (SSB) Press by Makiga is a manual press machine that produces stabilized soil blocks (SSB). This can be various shapes, interlocking (ISSB) or non-interlocking. Makiga proposes that the press can produce blocks used for affordable housing, water storage and sanitation solutions.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

Manufacturing/Building Method

Stabilized Soil Press can be used on a construction site or a small production facility.

Intellectural Property Type

Patent Protected

User Provision Model

The user buys directly from Makiga. They can contact the different offices in Africa, inquire directly on the website or contact them in social media to learn more.

Distributions to Date Status

Hundreds of thousands of construction machines have been exported.

Design Specifications

To manufacture an ISSB using this press, first the soil, cement and water is mixed. The ratio varies depending on the desired outcome. The mix is then placed inside the press and the lever is pushed down to compress the block. After this, the lever is turned to the other side to lift the block out of the press. The brick should be sprayed with water for the next seven days in order to cure it. Finally it must be left to dry cure for another 7 days. The press has four designs to create blocks of different shapes.

| Type of block | Height | Width | Length |

| Straight double interlocking block | 115 | 140 | 290 |

| Curved double interlocking block | 140 | ||

| Wide format interlocking block | 115 | 220 | 230 |

| Straight simple interlocking block | 115 | 140 | 290 |

| Grooved double interlocking block | 115 | 140 | 290 |

Technical Support

The purchase includes training on operation and maintenance and an illustrated manual.

Replacement Components

It uses motor oil for lubrication. Repair can be made locally with welding and scrap materials.

Lifecycle

Unknown.

Manufacturer Specified Performance Parameters

Produce stabilized soil blocks as strong as concrete blocks, in a low cost, eco-friendly and durable way. In an 8 hour day with 4 users, the machine should be able to produce 500 bricks.

Vetted Performance Status

All machines are tested before leaving the plant. The blocks have been tested to have a minimum compressive strength of 2.5 N/mm².

Safety

The machine must be placed on a leveled surface so there is no risk of it tipping over. Only trained personnel should operate it.

Complementary Technical Systems

A machine for roof tiles can paired to construct a complete building.

Academic Research and References

None found.

Compliance with regulations

Kenya Bureau of Standards (KS012070), Uganda Bureau of Standards

Other Information

Makiga has a range of machines available for different applications in construction.

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Have thoughts on how we can improve?

Give Us Feedback

https://es.wikipedia.org/wiki/Bloque_de_tierra_comprimida