Agriculture

November 9, 2023

Updated on November 9, 2023

·Created on July 21, 2017

Precast concrete beams and slabs (or planks and joists) is a construction system comprised of precast concrete elements that span in modules between walls and are tied together with rebar that locks into a thin cast-in-place slab.

Precast concrete beams and slabs (or planks and joists) is a construction system that constitutes either precast concrete arched panels, hollow mini-slabs, or planks that are placed between smaller, more frequently spaced precast beams or joists that are spanning between walls or columns. A thin reinforced concrete layer is then poured on top. The precast system doesn’t require the extensive formwork of a cast-in-place concrete slab, and is more flexible for projects that need to be phased such as the improvement of buildings in informal settlements. An example of a manufacturer of precast concrete beams and slabs is Nyati Slabs in South Africa. It is also a common construction method in India.

Target Users (Target Impact Group)

Distributors / Implementing Organizations

The manufacturers are the distributors of the product. The product can also be made on the construction site by an implementing NGO or general building contractor.

Manufacturing/Building Method

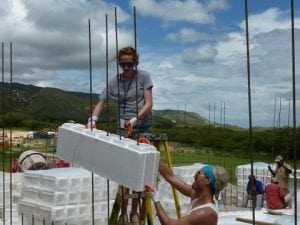

Made to order by a manufacturer and delivered to the construction site in pieces, or precast on site by a general building contractor. The pieces are then assembled on site and the final top layer of concrete is cast in place.

Intellectural Property Type

Other

User Provision Model

Users obtain the product directly from the manufacturer or through a general contractor.

Distributions to Date Status

Unknown.

Design Specifications

Precast elements come in all shapes and sizes. Some slab units are mini arched panels while others are hollow core and others are planks. Beams and joists either have a rectangular cross section or are the shape of T's both right-side up or upside-down. All precast components are individually reinforced with steel and specifications vary depending on local structural requirements and regulations. A slab is then poured on top of the system and thicknesses also vary.

Technical Support

Technical support would be provided by a general building contractor.

Replacement Components

Although the pieces are modular, because there is a thin slab poured on top of the assembly, it would be difficult to replace any components inside the system. It would be possible to buy new components from the manufacturer or precast new components on site for the later expansion of a building.

Lifecycle

If built to high quality standards, concrete can last for decades.

Manufacturer Specified Performance Parameters

Performance targets for this type of construction include affordability and flexibility in construction phasing.

Vetted Performance Status

Structural engineers should be consulted in the design of precast concrete slab/plank and beam/joist systems. Academic research has been performed related to precast concrete components (see Academic research section), but it does not necessarily inform construction projects, particularly in developing countries.

Safety

Workers are subject to the general risks of working from heights and with sharp tools.

Complementary Technical Systems

Precast concrete beams and slabs can be used with concrete block walls or cast concrete walls or columns, steel columns, or load-bearing brick walls.

Academic Research and References

Cavaco, E. 2017. Effects of corrosion on the behaviour of precast concrete floor systems.

Henin, E E A. 2012. Efficient precast/prestressed floor system for building construction. The University of Nebraska – Lincoln, ProQuest Dissertations Publishing.

Compliance with regulations

Regulations vary by country. The Precast/Prestressed Concrete Institute offers guide specifications for architectural and structural precast concrete. India also has standards for precast reinforced concrete planks and joists.

Other Information

Another method of onsite casting involves casting sections of slab one on top of the other and then moving the section into place. The sections can be cast solid or on top of a styrofoam layer.

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Agriculture

November 9, 2023

Implemented by

mWater

Agriculture

November 9, 2023

Have thoughts on how we can improve?

Give Us Feedback